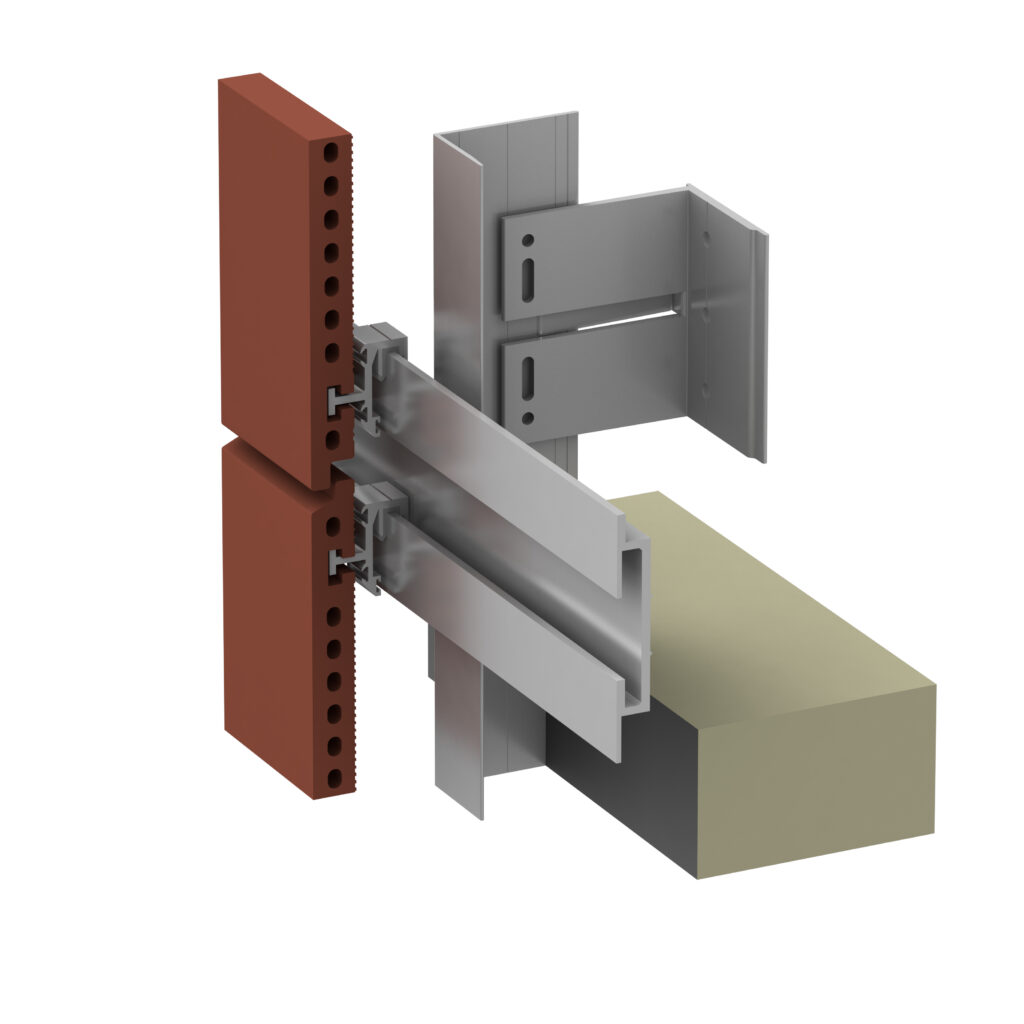

Terra Cotta Facade Cladding

Terra cotta facade cladding is a distinguished architectural solution that combines the timeless beauty of traditional materials with the advanced performance of modern construction techniques. As a versatile and aesthetically pleasing option, terra cotta cladding offers numerous benefits for both residential and commercial buildings.